Round belts for your individual applications

Many products large and small are manufactured, packaged and shipped on highly automated industrial processing equipment. Accordingly, there is a wide variety of machines and conveyor technology solutions that are used. BEHAbelt is specialized in the production of weldable round belts as well as V-belts and special profiles. Thanks to our own tool shop and modern, flexible production lines, we are able to produce customer-specific profiles quickly and cost-effectively.

PU60A soft blue smooth

PU75A red smooth

PU80A safe blue smooth,

metal detectable

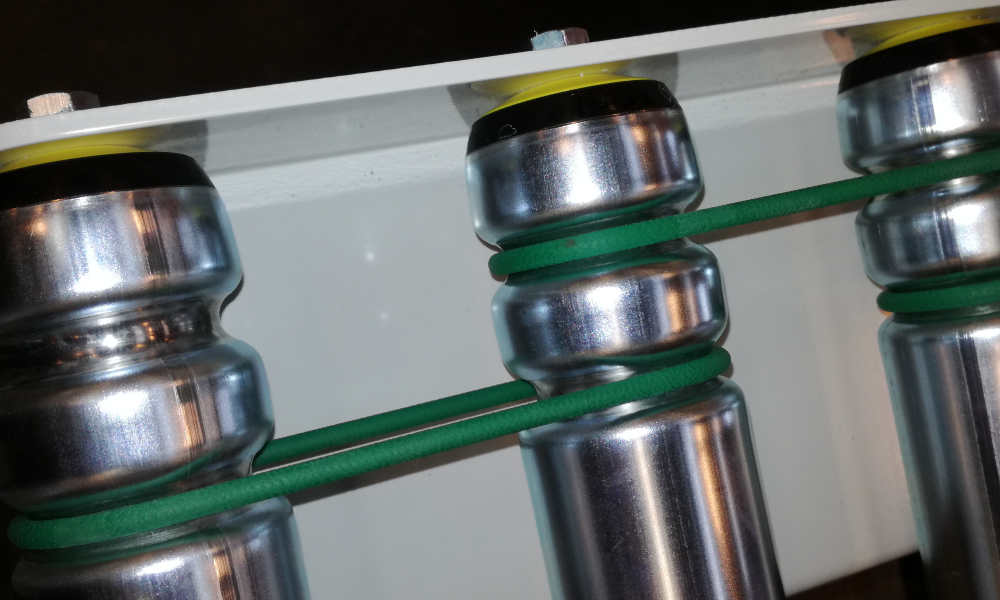

PU85A green rough,

reinforced Aramid

Which characteristics do the BEHAbelt round belts have?

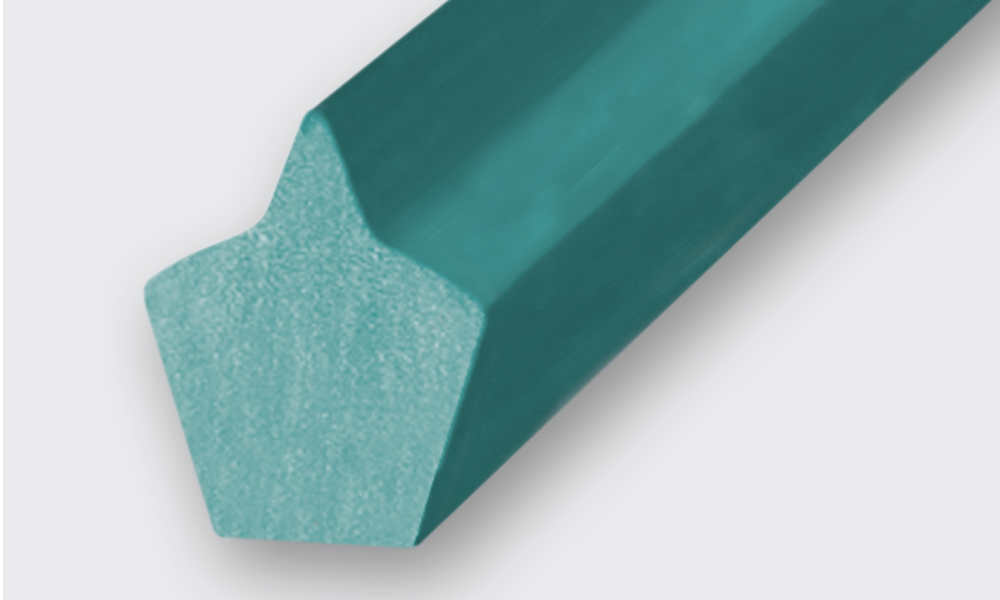

BEHAbelt offers a wide range of belt profiles. The products are available in several shore hardness grades and different surfaces (smooth, rough) to ensure optimum drive and transport properties as well as a long service life. Depending on the area of use and application, the round belts can be reinforced with different reinforcement materials (polyester, aramid, steel and weldable glass fibre PU).

What material are the round belts made of?

BEHAbelt uses high-quality PU (polyurethane) and TPE (polyester) materials for the production of round belts, which guarantee an optimal performance and long service life in conveyor technology applications.

In which diameters are the BEHAbelt round belts available?

As standard BEHAbelt produces round belts between 2 mm and 20 mm diameter. Often round belts are required to have a diameter of 3mm, 4mm, 5mm, 6mm and 8mm, but especially for higher load conditions round belts are also common in the range of 10mm, 12mm, 15mm or even 18mm and 20mm. Round belts with reinforcement are also required for high loads or long belt lengths.

BEHAbelt is a specialist for the design of special characteristics for round belts

As a result of our own production and the direct access to the different requirements in the market, BEHAbelt is able to offer a kind of modular system for the upgrading of round belts to optimise your installation.

The following special characteristics are offered:

PU safe (metal and X-ray detectable round belts): These PU round belts make an important contribution to food safety, because detached plastic particles can be detected by metal detectors and X-ray units.

Hydrolysis resistance (HY): The use of hydrolysis-resistant raw materials guarantees a longer service life, especially in humid environments, at higher temperatures and regular cleaning.

UV-C resistance: Special additives increase the resistance of the round belts to UV-C waves, which can lead to premature ageing of conventional plastics. This extends the service life of the belts, especially when UV-C lamps are used for surface decontamination.

Antistatic dissipative: By adding special additives, electrostatic charge is automatically dissipated via the sliding base or reversing drum, which ensures better transfer of products in the paper industry, for example, and prevents damage to electronic components in the conveyor section.

Low-temperature flexibility: For applications in the deep-freeze and low-temperature range, we offer material combinations that retain their flexibility and product characteristics at temperatures down to -30°C.

PU Plus (reduced elongation): The unique BEHAbelt materials PU75A and PU85A „PLUS“ optimize the elongation performance of round belts, i.e. the dimensional stability, in critical applications.

Food safety: FDA/EC conformity for all profile surfaces. USDA conformity for smooth profile surfaces.

In which applications are round belts often used?

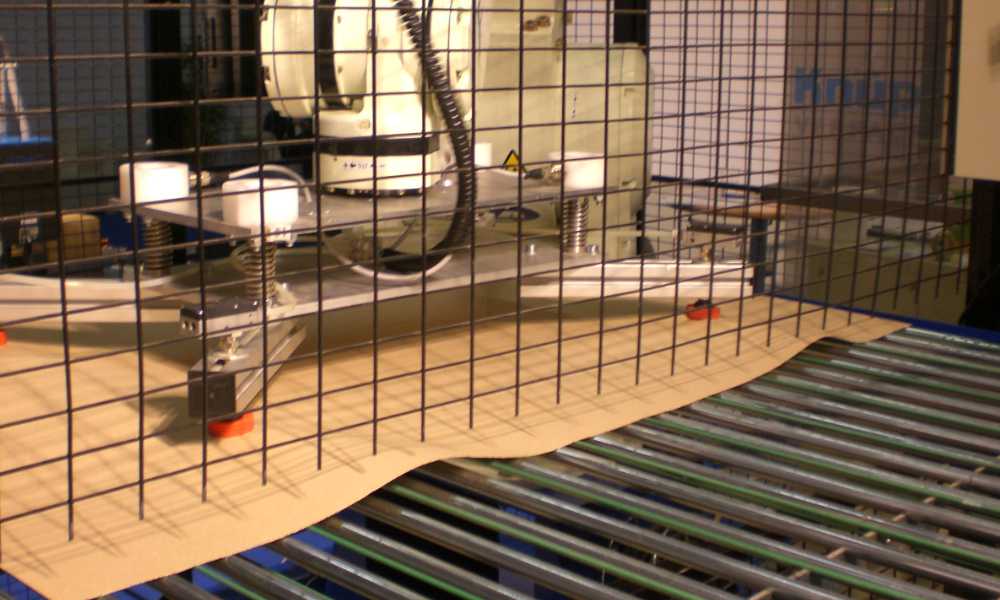

The wide range of round belts made of PU and TPE by BEHAbelt allows the optimal selection of the most suitable product for applications in the conveying or transmission technology.

In the following you will find an overview of some typical application areas.

Food industry (e.g. pizza topping lines, transport of sliced products in slicer lines)

Packaging industry (e.g. feeder or transport belts in packaging machines, paper cutting machines)

Wood processing, furniture manufacturing

(e.g. general applications in furniture factories)

Printing and paper (e.g. paper conveyor systems, cutting machines)

Logistics, intralogistics, material handling (roll-to-roll conveyor systems, crossed drives, tangential drives)

Building materials industry (conveyor systems)

What makes round belts different from other belt profiles?

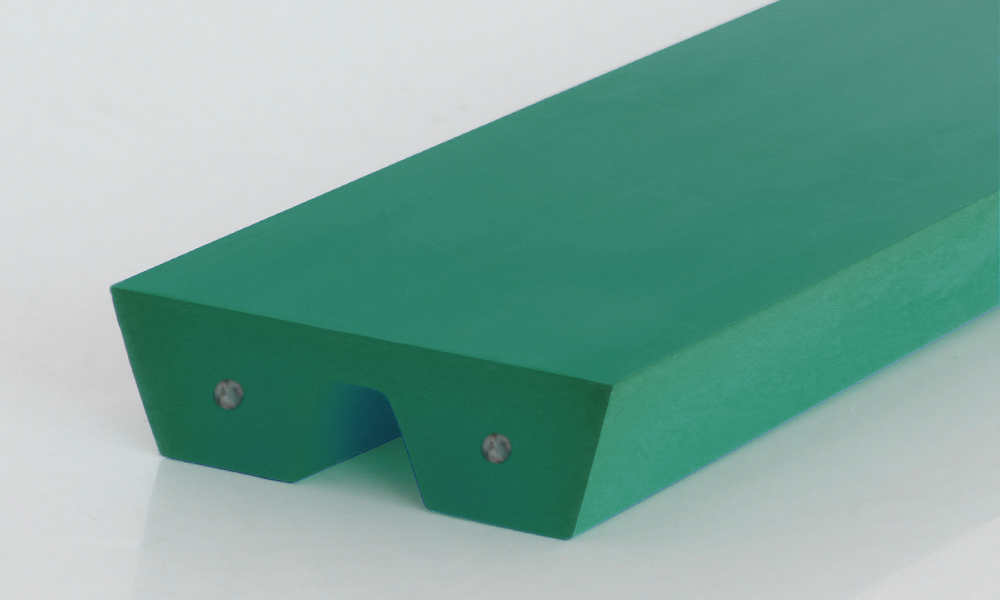

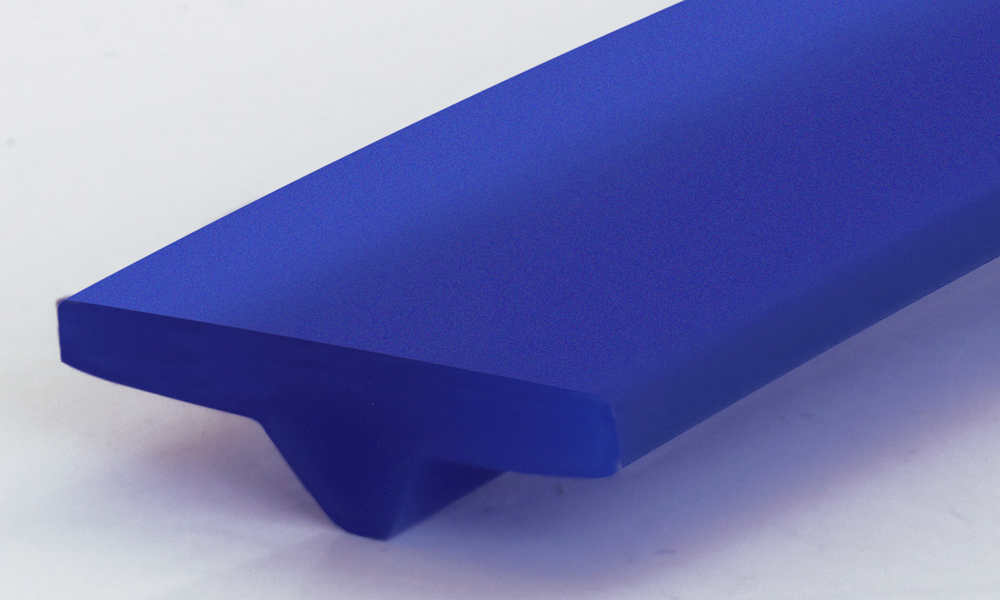

It is generally recommended that round belts are used in appropriate round belt pulleys and not in V-belt pulleys. In addition to conventional round belts, there are also so-called hollow round belts, which have the property that the connection is made with a nipple. V-belts represent the second large group of belt profiles; these are initially available in DIN 2215 dimensions and are supplemented by special designs, such as parallel V-belts (twin v-belts), double V-belts or V-belts with a vaulted top.

Furthermore BEHAbelt offers ridge top V-belts (tile industry), T-profiles, square or U-profiles and a lot of other special profiles which can be developed and manufactured according to customer specifications thanks to our own tool shop.

Is it possible to use round belts as transmission belts?

Yes, round belts are ideally suited as drive belts. They are resistant and very elastic. This makes installation easy and a tensioning device is not required. A wide range of Shore hardnesses in combination with different diameters is available for drive requirements. Furthermore, the round belts are available with smooth or roughened surfaces.

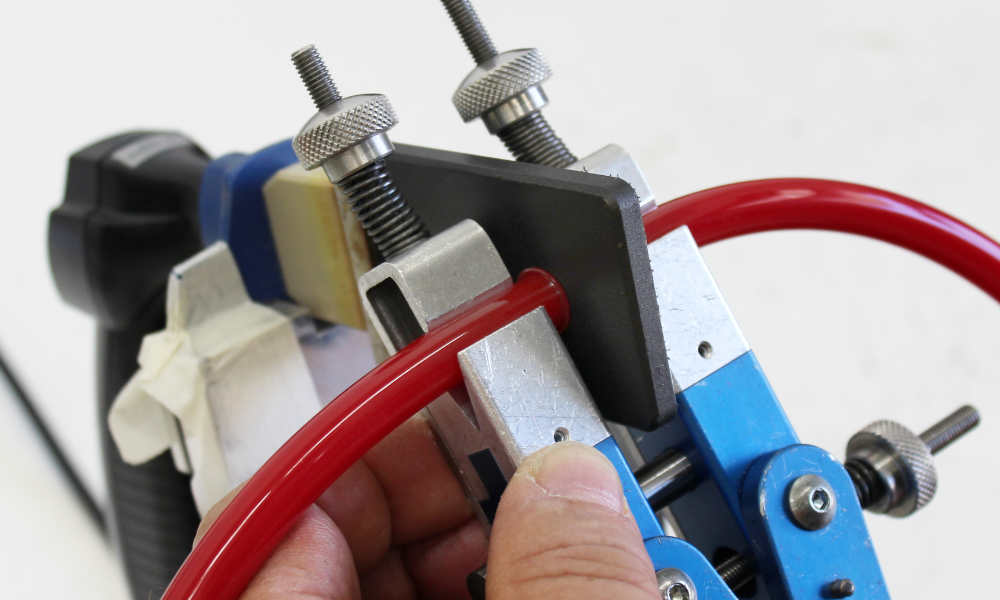

What is the correct way to weld round belts?

Round belts from BEHAbelt can be purchased by the meter, made up endlessly, delivered or welded on site.

There are two ways of welding round belts, either butt welding (for non-reinforced profiles) or overlap welding (for profiles with reinforcement).

Simplified, the welding process mainly takes place in four steps:

Preparing round belts

The belt ends are cut off by angle cut or 90° cut (e.g. with BEHAbelt AS02).

Clamping the belt in the guide unit

The guide unit or clamp (e.g. FZ01 Vario or FZ02/3) ensures perfect alignment of the belt ends to be spliced.

Welding belts

For PU belts 290°C are required, for TPE belts 240°C. The BEHAbelt welding units (e.g. EErgo) ensure a constant welding temperature even at different ambient temperatures.

Clean the belt

After the welding process and the cooling time only the welding bead has to be removed with a edge cutter (BEHAbelt SE02) or sharp knife.

A special feature for welding belts is the friction welding machine RS02. Here the belt ends are heated and welded by friction. This is the fastest and safest method to join belts endlessly.

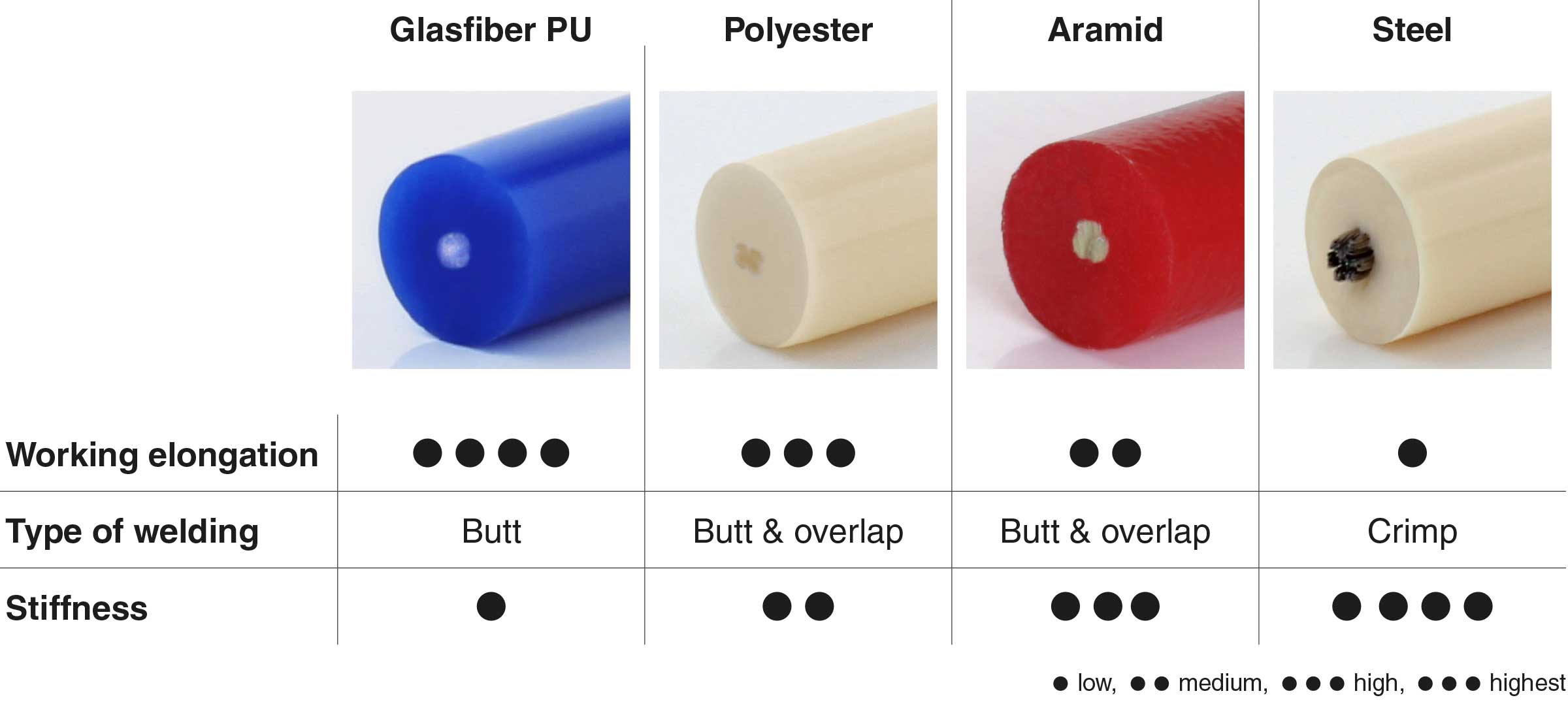

Comparison of the characteristics of the reinforcements

The use of reinforcement members in belt profiles provides more or less working elongation depending on the type, although the stiffness is opposite to this.

Where can I buy BEHAbelt round belts?

Round belts are available at technical specialised trade or directly at BEHAbelt.

It is important to us to support you with our experience in selecting the suitable round belt for your application.

All round belts at one glance Request samplesFurther belt profiles from BEHAbelt

Depending on the material to be conveyed, different belt profiles are required. BEHAbelt is specialized in the production of extruded thermoplastic belt profiles. Thanks to our own tool shop and modern, flexible production facilities, we can also produce customer-specific profiles quickly and cost-effectively.